- MAISON

- Solution d'emballage

-

DES PRODUITS

- Emballage en poudre

- Machine d'emballage liquide

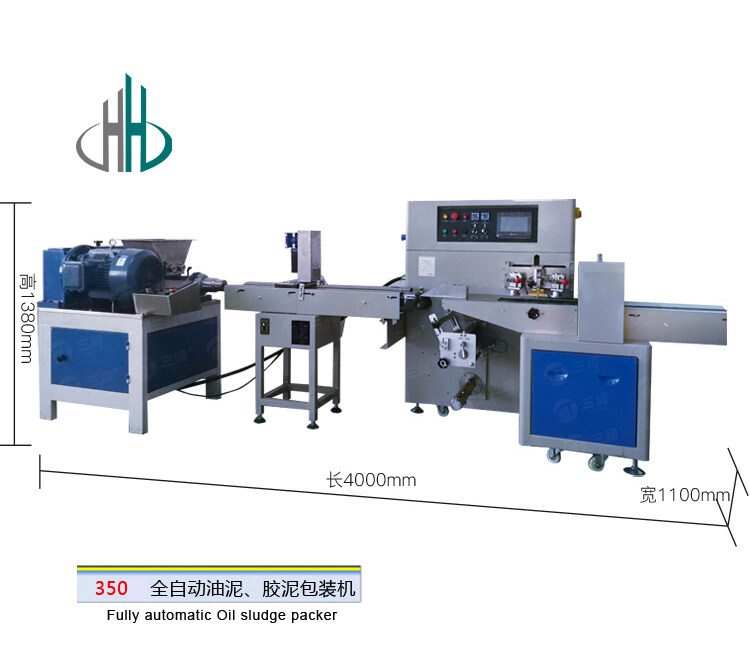

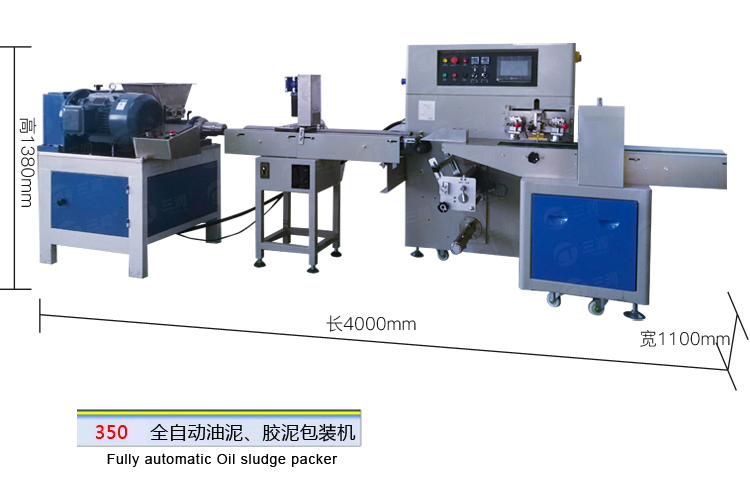

- Machine d'emballage matériel

- Machine d'emballage de granules

- Machine d'emballage de sacs à thé

- Machine de remplissage

- Machine d'emballage de fruits et légumes

- Machine d'emballage du narguilé

- Machine de remplissage et d'étanchéité de la cuillère de miel

- Machine d'emballage de débit

- Machine de coiffage et machine à visser en bouteille

- SOLUTION

- NOUVELLES

- À PROPOS DE NOUS

- CONTACTEZ-NOUS

Currency